|

USE OF SCRAPING TOOLS

When scraping is to be employed, it should be done with only those tools that are made for that purpose, i. e., Square Nose, Round Nose, Spear Point, Right and Left Skew. The handling of these tools will be found easy.

The only point to remember is that they should be held flat on the tool rest and parallel to the bed of the lathe when in use.

In general practice the ordinary skew chisel should not be used as a scraping tool, for the cutting edge is not sharpened to withstand the heavy strain required by such work. Should it be necessary, however, to use a skew chisel as a scraper, the tool should be held so that the top grind is parallel to the bed of the lathe while in use.

|

You can use calipers to check the width at any

point on your piece but stop the lathe as the

tool can easily catch and cause damae to

you, the piece, and your equipment. |

|

INTERNAL BORING

In roughing out the center for Napkin Rings, Jewel Boxes, etc., the quickest method is to work it out with a small gouge.

Place the gouge on the rest parallel to the bed of the lathe, having the point even with the center of the stock.

Force the gouge into the wood until a hole is bored to the depth required. If the hole is deeper than 1", remove the tool often and clear out the shavings in order not to burn the point.

In order to enlarge the hole to the proper size the point of the gouge is pressed against the left side of the hole a little above the center and a shearing cut is taken.

To obviate the danger of the tool catching, all cuts should start from the back of the hole and proceed toward the front.

|

Pic 1 |

|

Hollow Form

Internal boring on large pieces, such as vases, is commonly called Hollow Form turning.

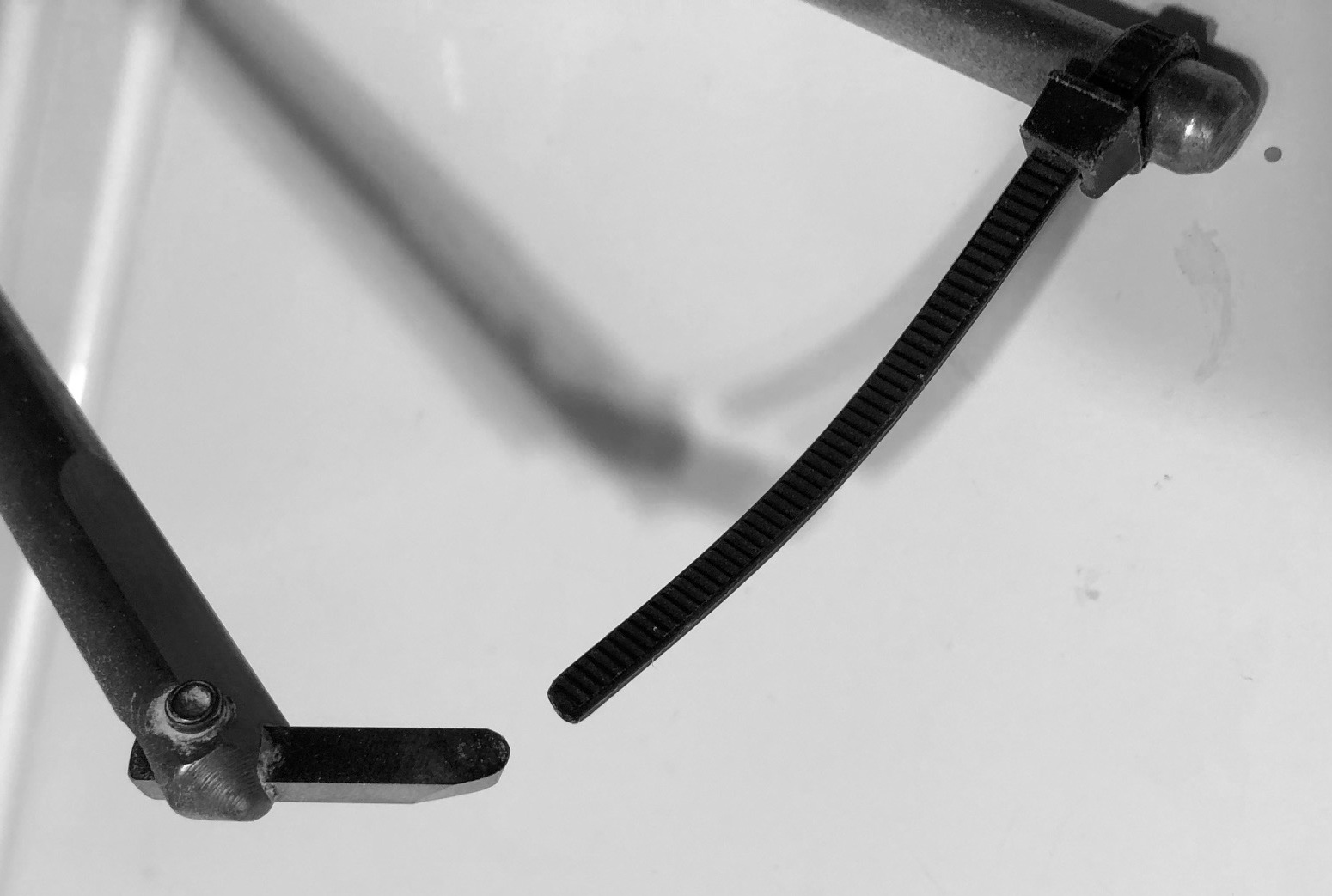

This can be a real challenge - especially as the size of the item increases. The force exerted on your tools can quickly become too much for standard tools and you must take the leap and purchase the proper high quality (and more expensive) proper turning tools. These tools have longer and sturdier handles to provide better leverage and better control. (See pic 2.) I have seen tools with handles as long as 4 foot long.

The outside of the piece can be shaped by turing between the tailstock and a faceplate or adjustable headstock jaws. Once the outside of the piece has been shaped make sure the piece is fastened securely to the faceplat/headstock.

|

Pic 2

|